-

2018-09-12150碟子

-

2018-09-13一次性環(huán)保餐具-碟子

-

2018-09-14一次性可降解餐具-270ml碗

-

2018-09-14一次性餐具-叉子

-

2018-09-14環(huán)保餐盒

首頁 - 資訊動(dòng)態(tài) > 公司快訊

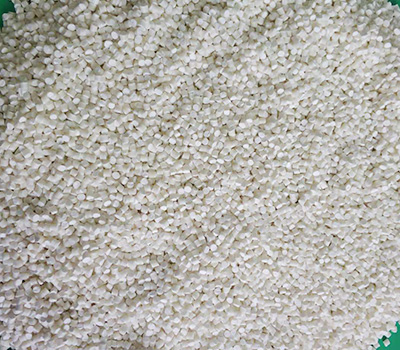

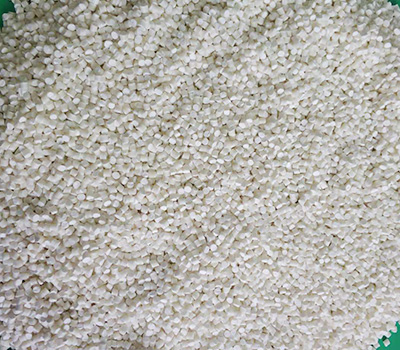

生物降解材料擠出造粒的外觀如何

你知道生物降解材料擠出造粒的外觀如何嗎?實(shí)際上要了解這個(gè)問題,我們可以從3個(gè)方面來進(jìn)行講解:

Do you know the appearance of extrusion granulation of biodegradable materials? In fact, to understand this problem, we can explain it from three aspects:

1.生物降解顆粒兩端的有孔問題:

1. Porosity at both ends of biodegradable particles:

兩端都有孔:說明料里含的低分子物質(zhì)戒水份較多,真空排氣沒抽干凈戒原料含的低分子戒水成分較多。

There are holes at both ends: it indicates that the material contains more low molecular weight water repellent substances, and the vacuum exhaust is not clean. The material contains more low molecular weight water repellent substances.

只有一端有孔:說明料里含的低分子物質(zhì)戒水份較少,沒有嚴(yán)格要求時(shí)可以接受。

Only one end has holes: it indicates that the low molecular substances in the material contain less water repellent, which can be accepted without strict requirements.

解決:前處理(干燥、密封等);加強(qiáng)真空排氣(同時(shí)要考慮到螺桿設(shè)計(jì));提高水槽溫度。

Solution: pretreatment (drying, sealing, etc.); Strengthen the vacuum exhaust (at the same time, consider the screw design); Raise the temperature of the sink.

2.生物降解顆粒發(fā)泡:

2. Biodegradable particle foaming:

出現(xiàn)多個(gè)孔,或者表面粗糙真空度不夠;溫度過高,原料成分的分解等。 原料含水分過高; 原料(較差的副牌料)不耐溫或成分使用不當(dāng),相互間化學(xué)反應(yīng)而發(fā)。

Multiple holes appear, or the surface roughness and vacuum degree are insufficient; High temperature, decomposition of raw materials, etc. The moisture content of raw materials is too high; The raw materials (poor sub brand materials) are not temperature resistant or the ingredients are improperly used, resulting from chemical reactions between them.

3.顆粒表面光滑平整問題:

3. The particle surface is smooth and flat:

顆粒表面光滑平整,要看所用的原材料的成分——玻纖、 無機(jī)礦物、表面較粗燥的阻燃劑等物質(zhì)。但相比對下, 同個(gè)料批次有差異,原因有:

The particle surface is smooth and flat, depending on the composition of the raw materials used - glass fiber, inorganic minerals, flame retardants with rough and dry surfaces, etc. However, there are differences in the same material batch compared with the following reasons:

① 塑化混煉不好,交叉分布不夠細(xì)加工溫度不夠,塑化不好;② 機(jī)器問題,如??撞黄秸?、不夠光滑等;③ 原料成分間相容性不好(也包括色粉色母在內(nèi)),出現(xiàn)分層、析出等。

① Poor plasticizing and mixing, insufficient cross distribution, insufficient fine processing temperature, poor plasticizing; ② Machine problems, such as uneven die holes and insufficient smoothness; ③ The compatibility between raw material components is not good (including pink mother), and delamination and precipitation occur.

以上就是對問題的解答了,您有什么想法或者需求,可以隨時(shí)來我們網(wǎng)站http://m.fs-sjg.com進(jìn)行咨詢了解!

The above is the answer to the question. If you have any ideas or needs, you can come to our website at any time http://m.fs-sjg.com Ask about it!

- 上一個(gè): 玉米淀粉顆粒一次性餐具的概念及使用優(yōu)點(diǎn)

- 下一個(gè): 高靜壓對玉米淀粉顆粒結(jié)構(gòu)的影響

150碟子

150碟子 一次性環(huán)保餐具-...

一次性環(huán)保餐具-... 一次性可降解餐具...

一次性可降解餐具... 一次性餐具-叉子

一次性餐具-叉子 環(huán)保餐盒

環(huán)保餐盒

相關(guān)產(chǎn)品: